Webbing Sling

A webbing sling is a flat strap, typically woven from high-tenacity polyester yarn, used for lifting, maneuvering, and securing cargo during transportation and industrial applications. They offer several advantages over traditional lifting methods like chains or wire ropes.

Key Features:

- Lightweight and Flexible: Compared to chains or wire ropes, webbing slings are significantly lighter and more flexible. This makes them easier to maneuver around tight spaces and easier to handle during rigging.

- Soft on Load Surfaces: The flat, wide surface of a webbing sling distributes the load more evenly, minimizing the risk of damage to delicate or finished goods.

- High Strength and Capacity: Despite their lightweight nature, webbing slings can handle significant loads, typically ranging from 1 ton to 36 tons or more, depending on the size and construction.

- Abrasion and Chemical Resistant: High-quality polyester webbing is resistant to abrasion, UV rays, and many chemicals, ensuring long-lasting durability.

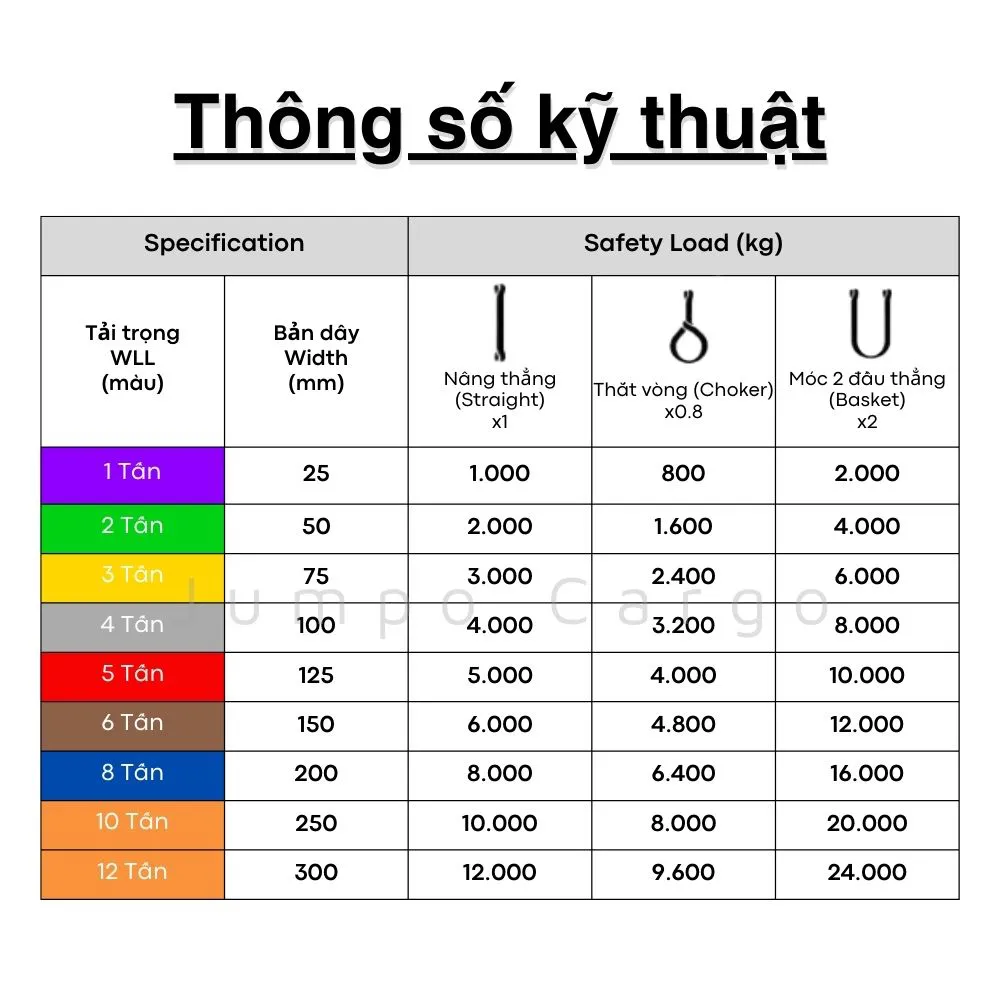

- Safety Factor: Webbing slings are designed with a built-in safety factor, meaning their working load limit (WLL) is a fraction of their actual breaking strength. This provides an extra margin of safety during lifting operations.

- Color-Coded Capacity: Webbing slings are often color-coded to easily identify their working load limit. This allows for quick and safe selection during lifting tasks.

Applications:

Webbing slings are versatile tools used in various industries, including:

- Construction: Lifting and securing building materials, machinery, and equipment.

- Manufacturing: Lifting and transporting raw materials, finished products, and machinery.

- Logistics: Securing cargo on pallets, crates, and trailers during transportation.

- Rigging: Lifting and positioning heavy objects during installation or maintenance projects.

- Events: Lifting and securing equipment for concerts, festivals, and other events.

Types of Webbing Slings:

There are various types of webbing slings available, each with its specific configuration for different lifting scenarios. Here are some common types:

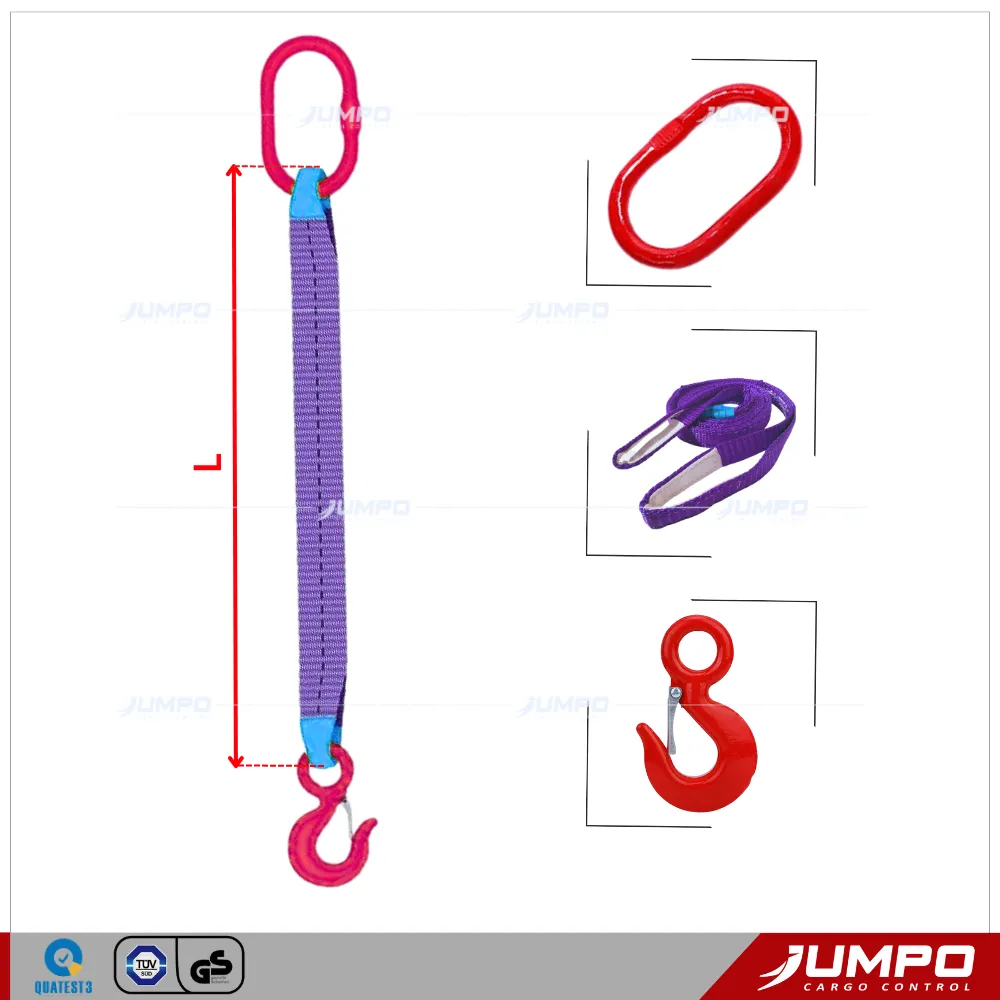

- Eye and Eye Slings: Feature loops at both ends for attaching to hooks or rigging points.

- Endless Slings: Continuous loop design, ideal for choker hitches or when a softer lifting surface is desired.

- Double Eye Slings: Similar to eye and eye slings but with a reinforced lifting area at each end.

- Multi-leg Slings: Feature multiple webbing straps connected to a central lifting point, ideal for lifting unbalanced or oddly shaped loads.

Important Considerations:

- Working Load Limit (WLL): Always choose a webbing sling with a WLL exceeding the weight of the load you intend to lift.

- Inspection and Maintenance: Regularly inspect webbing slings for signs of wear, damage, or cuts. Replace damaged slings immediately.

- Proper Use: Follow safe lifting practices and ensure webbing slings are used within their designated capacity and configuration.

By understanding these features and considerations, webbing slings can be a safe and effective tool for various lifting and material handling tasks

main.comment_read_more