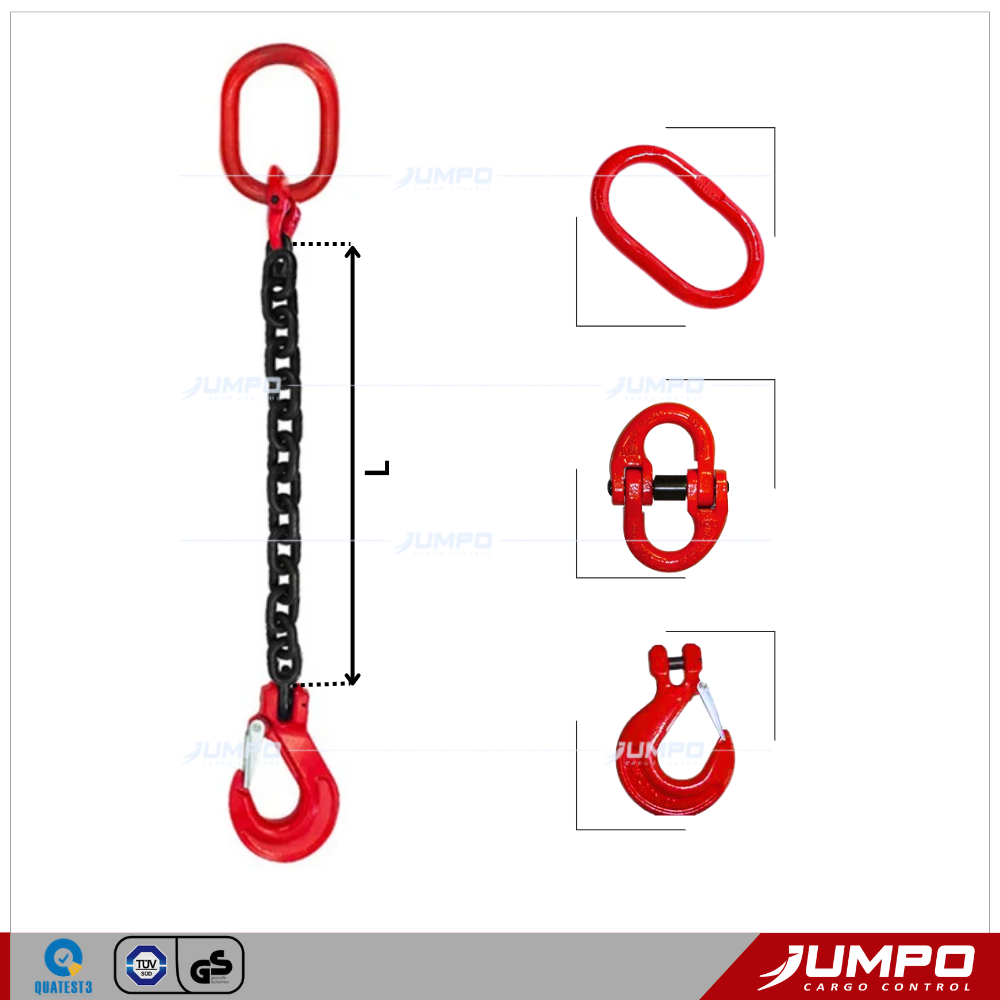

Chain Leg Slings

- Chain leg slings consist of high-grade steel chains that branch out into multiple "legs" – typically two, three, or four. Each leg features secure end fittings (like hooks or shackles) for attaching to various lifting points on your cargo.

Key Features:

- Exceptional Strength: Constructed from high-strength steel, chain leg slings are built to handle the most demanding loads, making them ideal for lifting heavy machinery, equipment, and other bulky cargo frequently encountered by Jumpo Cargo.

- Durability in Harsh Environments: Unlike webbing slings, chain slings are resistant to abrasions, cuts, and extreme temperatures, making them suitable for harsh industrial environments where Jumpo Cargo operates.

- Secure Grip on Uneven Surfaces: The rigid nature of chain allows it to grip uneven surfaces better than webbing slings, providing a secure hold on irregularly shaped cargo commonly handled at Jumpo Cargo facilities.

Applications for Chain Leg Slings at Jumpo Cargo:

- Lifting heavy machinery and equipment

- Maneuvering large metal objects and pipes

- Securing heavy cargo for transport

- Lifting containers and heavy building materials

Things to Consider When Using Chain Leg Slings at Jumpo Cargo:

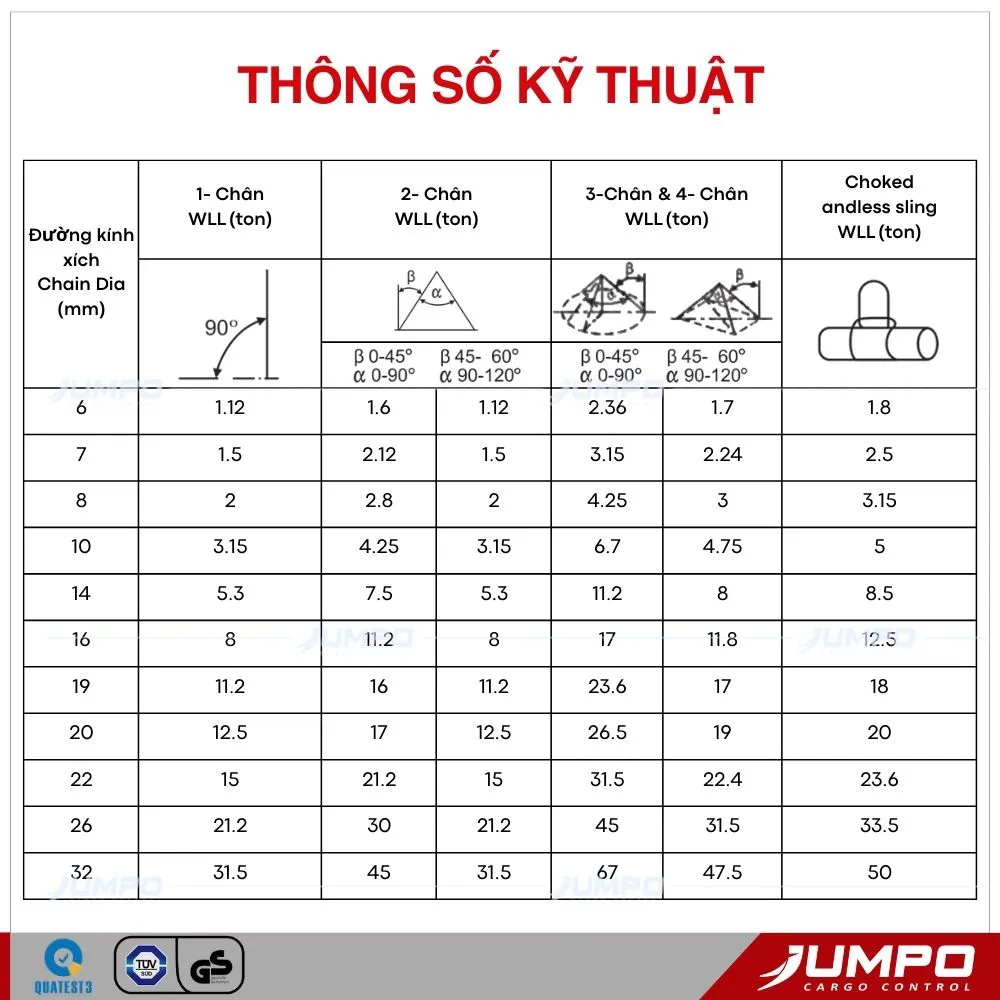

- Weight capacity: Ensure the sling's rated capacity exceeds the weight of your cargo. Chain leg slings typically have higher capacities than webbing slings.

- Number of legs: Choose a sling with the appropriate number of legs based on your lifting configuration and the weight distribution of your cargo.

- Safety precautions: Due to their weight and rigidity, chain leg slings require extra caution during lifting operations. Always follow proper lifting practices and ensure workers are aware of potential hazards.

Remember:

- Regularly inspect your chain leg slings for signs of wear and tear, damage, or corrosion. Following proper lifting practices and using slings within their rated capacity ensures safe and efficient operations at Jumpo Cargo.

main.comment_read_more